- Phone:+86 13705555767

- Tel:+86 0555-6797579

- Q Q:2159779366

- E-mail:amd@amdmt.com

- Address:Bowang Development Zone, Ma'anshan City, Anhui Province

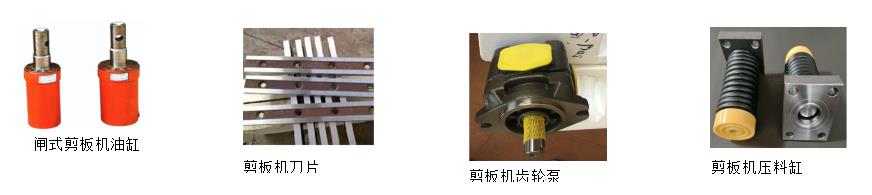

Performance and characteristics:

1. All steel plate welding structure is adopted to eliminate stress by vibration, which has good rigidity and stability. 2. It adopts ball screw and linear guide rail, servo control, and high positioning accuracy.

3. The tandem oil cylinder ensures that the shearing angle will not change when the machine tool is shearing.

4. The return of the accumulator is stable and fast.

5. The blade clearance is automatically adjusted, accurate, fast and convenient.

6. The shearing angle can be adjusted to reduce the distortion of the sheet metal.

7. The electric rear stopper and position display are convenient and accurate.

8. Roller type worktable can reduce the scratch of sheet metal and friction.

9. E21S or DA41, DA52S, DAC316S, DAC360S and other numerical control systems.

Technical Parameters of QC11K Hydraulic Gate Type CNC Plate Shear

model | Can be cut Plate thickness (mm) | Can be cut Board width (mm) | Throat and mouth depth (mm) | Rear blocking material distance (mm) | shear angle | trip frequency (min-1) | electric machinery power (KW) | External dimensions(mm) | weight(T) |

6×2500 | 6 | 2500 | 80 | 600 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | 5.3 |

6×3200 | 6 | 3200 | 80 | 600 | 0.5-1.3 | 12 | 7.5 | 3650×1750×1980 | 6.5 |

6×4000 | 6 | 4000 | 80 | 600 | 0.5-1.3 | 10 | 7.5 | 4650×1780×2075 | 7.5 |

6×5000 | 6 | 5000 | 80 | 600 | 0.5-1.3 | 8 | 7.5 | 5650×1830×2250 | 10.5 |

6×6000 | 6 | 6000 | 80 | 600 | 0.5-1.3 | 8 | 7.5 | 6650×1890×2380 | 15.2 |

8×2500 | 8 | 2500 | 80 | 600 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | 6 |

8×3200 | 8 | 3200 | 80 | 600 | 0.5-1.3 | 12 | 7.5 | 3850×1750×1980 | 6.8 |

8×4000 | 8 | 4000 | 80 | 600 | 0.5-1.3 | 10 | 7.5 | 4650×1850×2075 | 8.5 |

8×5000 | 8 | 5000 | 80 | 600 | 0.5-2 | 7 | 15 | 5850×2000×2500 | 12.5 |

8×6000 | 8 | 6000 | 100 | 600 | 0.5-2 | 7 | 15 | 6805×2115×2715 | 19.8 |

10×2500 | 10 | 2500 | 120 | 600 | 0.5-2.3 | 10 | 15 | 3195×1800×2210 | 8.2 |

10×3200 | 10 | 3200 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | 9.15 |

10×4000 | 10 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 1695×1930×2275 | 11 |

10×5000 | 10 | 5000 | 120 | 600 | 0.5-2.3 | 5 | 15 | 5905×2115×2715 | 16 |

10×6000 | 10 | 6000 | 120 | 600 | 0.5-2.3 | 5 | 15 | 6905×2215×2800 | 22 |

12×2500 | 12 | 2500 | 120 | 600 | 0.5-2.3 | 10 | 15 | 3195×1800×2100 | 8.7 |

12×3200 | 12 | 3200 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | 9.8 |

12×4000 | 12 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 4710×1950×2485 | 13.4 |

12×12000 | 12 | 12000 | 150 | 1000 | 0.5-3 | 5 | 75 | 12780×3800×4400 | 110 |

12×6000 | 12 | 6000 | 120 | 600 | 0.5-2.3 | 4 | 18.5 | 7000×2300×3100 | 29 |

16×2500 | 16 | 2500 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3215×1880×2340 | 9 |

16×3200 | 16 | 3200 | 120 | 600 | 0.5-2.3 | 7 | 15 | 3915×1880×2445 | 11 |

16×4000 | 16 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 4715×1950×2590 | 15 |

16×5000 | 16 | 5000 | 120 | 600 | 0.5-3 | 5 | 22 | 6000×2300×3000 | 23 |

16×6000 | 16 | 6000 | 120 | 600 | 0.5-3 | 4 | 37 | 7000×2300×3100 | 36 |

20×2500 | 20 | 2500 | 120 | 600 | 0.5-3 | 6 | 22 | 3215×1890×2465 | 11 |

20×3200 | 20 | 3200 | 120 | 600 | 0.5-3 | 5 | 30 | 4120×2890×2780 | 18 |

20×4000 | 20 | 4000 | 120 | 600 | 0.5-3 | 4 | 30 | 4925×2150×2900 | 21 |

20×5000 | 20 | 5000 | 120 | 600 | 0.5-3 | 4 | 37 | 6000×2300×3050 | 29 |

25×2500 | 25 | 2500 | 120 | 600 | 0.5-3.5 | 5 | 30 | 3435×2000×2710 | 15.3 |

25×3200 | 25 | 3200 | 120 | 600 | 0.5-3.5 | 5 | 30 | 4120×2200×3000 | 21 |

25×4000 | 25 | 4000 | 120 | 600 | 0.5-3.5 | 3 | 30 | 4950×2200×3150 | 26 |

30×2500 | 30 | 2500 | 120 | 600 | 1-3.5 | 4 | 30 | 3135×2020×2770 | 17 |

30×3200 | 30 | 3200 | 120 | 600 | 1-3.5 | 3 | 37 | 4200×2300×3200 | 23 |

40X2500 | 40 | 2500 | 120 | 1000 | 0.5-4 | 3 | 55 | 3300x2180x2730 | 27 |

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

EN

EN ZH

ZH